ISO Lathe Turning Tools

Uses and Machining Tips

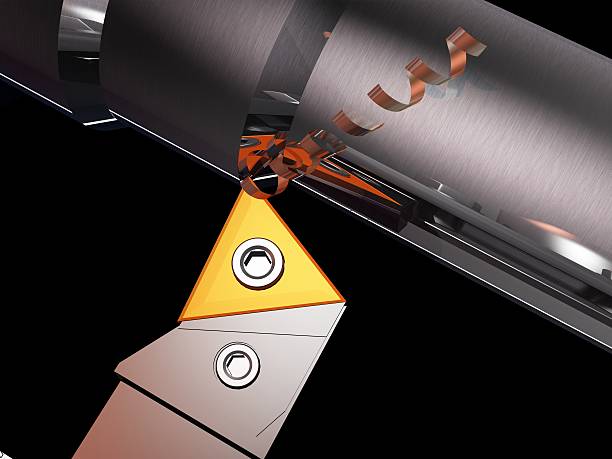

ISO lathe turning tools are standardized cutting tools used in CNC and manual turning applications. These tools follow ISO (International Standards Organisation) codes, which define the insert shape, clearance angle, tolerance, size, and chipbreaker type. This makes it easier to identify, replace, and use the right tool across different machines and brands.

Where ISO Turning Tools Are Used

You’ll find ISO turning tools in:

- General metalworking shops

- CNC production lines

- Toolrooms and maintenance workshops

- Automotive, aerospace, and industrial manufacturing

Common operations include:

- Facing – smoothing the end of a workpiece

- External turning – reducing outer diameter

- Profiling – cutting complex shapes

- Grooving and parting – cutting grooves or separating parts

- Threading – external and internal threads

Materials machined with ISO tools:

- Mild and stainless steel

- Cast iron

- Aluminium

- Brass and copper alloys

- Hardened steels (with suitable carbide inserts)

ISO Insert Shapes (Quick Guide)

| Code | Shape | Common Use |

|---|---|---|

| C | 80° rhombic | General turning and profiling |

| D | 55° rhombic | Fine profiling and finishing |

| S | Square | Strong insert for heavy roughing |

| T | Triangle | Light to medium turning |

| W | Trigon | Good edge strength, finishing work |

Tips for General Machining with ISO Tools

- Match insert to material

Use the correct carbide grade and coating. Example:- Steel: P-grade carbide (TiN or TiAlN coating)

- Stainless: M-grade carbide

- Aluminium: Uncoated or diamond-coated

- Set the correct cutting speed

Too slow = built-up edge.

Too fast = insert wear.

Always refer to toolmaker’s cutting data. - Use proper feed rate and depth of cut

Roughing needs higher feed and depth.

Finishing needs lighter cuts. - Check tool overhang

Keep it as short as possible to reduce vibration and tool chatter. - Use the right chipbreaker

Choose chip control geometry that suits your operation and material. Poor chip control reduces finish quality and damages inserts. - Secure clamping

Make sure the insert is seated properly. Loose inserts wear out faster and compromise accuracy. - Keep tools sharp

Don’t run inserts too long. Replace or rotate before the edge breaks down.