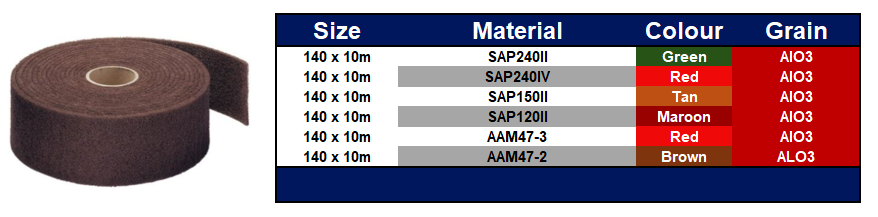

Standard Non-Woven Abrasive Fleece Rolls / Scotch Brite Rolls

Standard non-woven abrasives fleece, commonly known as “Scotch-Brite” material, is a versatile industrial abrasive used for surface preparation, finishing, and cleaning applications.

Construction and Materials

Non-woven fleece with abrasive added. Nylon base bonded by resin. The material consists of a sparse unwoven polymer such as cellulose, nylon or spun polypropylene fiber that creates an open web structure. Products use several variations of hardening and abrasive materials, such as aluminum oxide (alumina), titanium dioxide and resins.

Abrasive Types

The material comes in two main abrasive grain categories:

- ‘A’ Grades (e.g., CA): use aluminium oxide grit

- ‘S’ Grades (e.g., MS): use silicon carbide grit

Grade Classifications

Non-woven abrasives are typically available in various grades based on aggressiveness:

- Coarse: For removing scale, rust, heavy deburring, flashings, paint and coatings

- Medium: For lighter surface prep and cleaning, weld cleaning, blending, light deburring

- Fine: For light cleaning, blending

Common grit equivalents range from Extra-Coarse(50 grit), Coarse(60-80), Medium(100-150), Fine(180-220), Very Fine(240-360), Super Fine(400), Ultra Fine(600).

Applications

Scotch-Brite™ Industrial Abrasives are ideal for metalworking applications like deburring, finishing, blending and more. They’re commonly used as alternatives to steel wool, or other non-woven pads and are suitable for both metal and wood finishing applications.

Available Forms

The material is manufactured in various formats including:

- Hand pads (commonly 6″ x 9″)

- Discs and wheels

- Belts

- Individual sheets or lengths of flat-stock straight-edge abrasives

- Roll stock

The open web construction allows for consistent finishing while preventing loading, making these materials particularly effective for conditioning and surface preparation tasks across multiple industries.

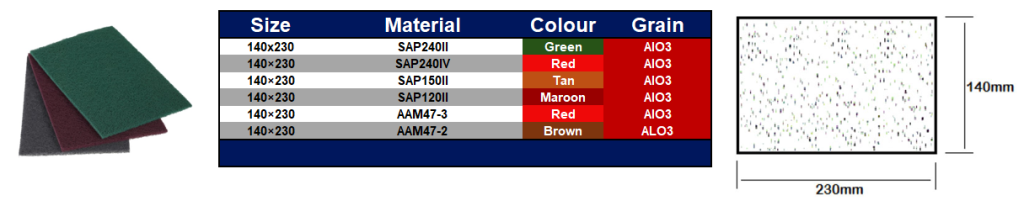

Standard Non-Woven Abrasive Fleece Sheets / Scotch Brite Pads