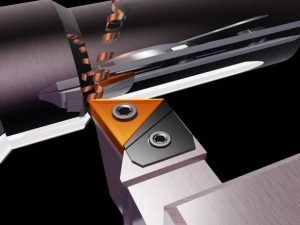

Types of Bonded Abrasives

Bonded abrasives consist of abrasive grains held together by a bonding agent. The main categories include:

Vitrified Bonds – Glass-like ceramic bonds that are hard, porous, and heat-resistant. Common in grinding wheels but not typically used for flexible products like sanding belts.

Resin Bonds – Synthetic polymer bonds that provide flexibility and shock resistance. These are widely used in sanding belts, cut-off wheels, and flap discs.

Rubber Bonds – Flexible bonds that allow for conformable grinding and polishing operations.

Metal Bonds – Used primarily for diamond and CBN wheels in precision grinding applications.

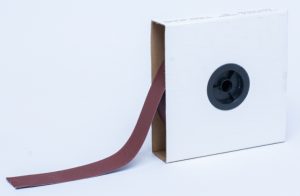

Sanding Belt Materials

For sanding belts specifically, the construction involves several key components:

Abrasive Grains

– Aluminium Oxide – Most common, good for wood, metal, and general-purpose applications

– Silicon Carbide – Harder and sharper, excellent for non-ferrous metals, glass, and stone

– Zirconia Alumina – Self-sharpening, ideal for heavy-duty metal removal

– Ceramic Alumina – Premium option for aggressive cutting and long life on stainless steel

Backing Materials

– Paper (A, C, D, E weights) – Lightweight, conformable, good for fine finishing

– Cotton Cloth (J, X, Y weights) – More durable and flexible than paper

– Polyester Cloth – Superior strength and heat resistance

– Film/Polyester Film – Ultra-smooth finish for precision applications

Bond Types for Belts

– Hide Glue – Traditional natural adhesive, still used for some woodworking applications

– Resin-over-Resin – Synthetic bond providing consistent performance and heat resistance

– Resin-over-Size – Size coat seals the backing; resin makes coat hold abrasive grains

Joint Types

– Butt Joint – Edges butted together, smoothest running

– Overlap Joint – More economical but creates a bump during operation

– Bias Joint – Cut at an angle for smoother operation than overlap