Wide Belt Sanding Operation

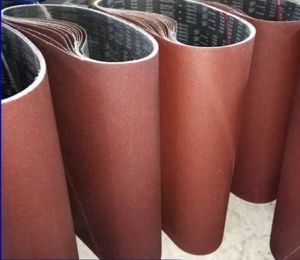

Wide belt sanding is a high-production method for surface preparation and finishing that uses large abrasive belts to process materials efficiently. Here’s comprehensive information about wide belt sanding and the available material options:

Wide Belt Sander Specifications

Wide belts for sanding or finishing large flat surfaces and for abrasive planning or lumber dimensioning. Wide belts are sanding belts that are 13 inches in width or more. Red Label manufactures wide belts with widths up to 54″ and lengths up to 128″. More commonly, these larger belts range from 25 inches up to 52 inches in width, and lengths from 48″ up to 103″.

The abrasive belt speed for these machines is in the neighborhood of 8,000 plus sfpm (~90 mph).

Abrasive Grain Options

Wide belt sanders accommodate several types of abrasive materials:

Primary Abrasive Types

Choose from options such as Aluminium Oxide, Zirconia, Ceramic, Silicon Carbide, or non-woven materials, based on the material and project goals.

- Aluminum Oxide: Aluminum oxide remains the most popular choice for general-purpose applications, offering excellent value and versatility across ferrous metals, wood, plastics, and composite materials. It’s highly friable, meaning that the grain tips fragment during use to continually provide a sharp cutting surface.

- Zirconia Alumina: Premium grain for heavy stock removal and longer belt life on hard materials

- Ceramic Aluminum Oxide: Advanced grain technology for aggressive cutting and extended belt life

- Silicon Carbide: Best for non-ferrous metals, glass, and stone applications

- Non-woven: For light finishing and surface conditioning

There are seven abrasive minerals; Natural; Emery, Garnet Synthetic; Aluminum Oxide, Silicon Carbide, Alumina-Zirconia, Ceramic Aluminum Oxide, Diamonds

Backing Material Options

The backing material significantly affects belt performance and durability:

Cloth Backings

There are three common weights of cloth backed belts – J-Weight, X-Weight & Y-Weight (listed from most to least flexible). Both J and X weight belts have cotton cloth backs while Y weight is generally polyester or a poly/cotton blend.

- J-Weight: Most flexible, cotton cloth backing

- X-Weight: Medium flexibility, cotton cloth backing

- Y-Weight: Least flexible, typically polyester or poly/cotton blend

Polyester/Cotton Blends

Aluminum oxide, X-wt. 65/35 Poly/Cotton: The backing, a Polyester/Cotton blend is very durable. Good general-purpose material for most metal applications. With a great initial price point, the Poly/Cotton backing offers a durable belt with good grain retention. Great starting point for most metal applications.

Specialized Backings

- Polyester Film: Polyester film is the newest type of backing that serves as a base for all grades of mineral grains. Used in Imperial brand lapping film for precision finishing

- Paper Backing: Available for lighter applications

- Waterproof Options: Only polyester backings can be used on applications utilizing water soluble oils as this is the only backing type that is naturally waterproof

Grit Selection

Grit size determines coarseness. Choose between coarse (for material removal), medium (for general sanding), or fine (for finishing) grits.

Common grit ranges for wide belt applications include:

- Coarse removal: P36-P80 grits

- General sanding: P100-P240 grits

- Fine finishing: P280-P400+ grits

P36–P80: Polyester cloth backing >> P100–P240:X-weight cotton cloth backing shows typical backing material selections by grit range.

Applications

Wide belt sanders are used across multiple industries for:

- Lumber dimensioning and surface preparation

- Metal finishing and deburring

- Composite material processing

- Large panel sanding

- Production finishing operations