Choosing the Best Sanding Belt Joint for Wood Finishing

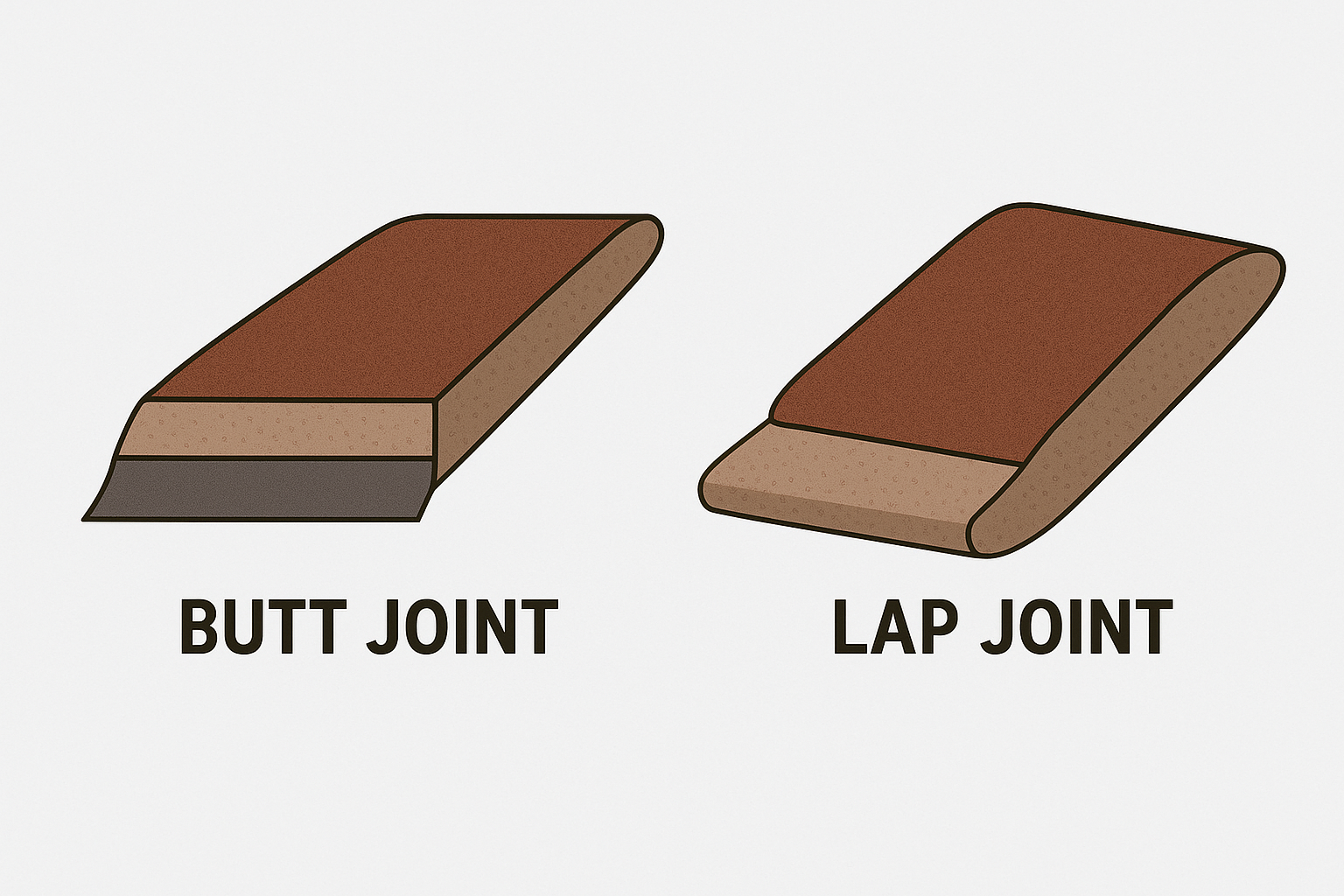

When working with sanding belts on wood, the type of joint makes a big difference. A poor joint leaves visible lines or bumps on the surface, especially during fine finishing. The two most common joints are butt joints and lap (skived) joints.

- Butt Joints The belt ends are cut square and joined with tape placed underneath.

- The tape creates a slight ridge that transfers to the workpiece.

- On softwoods or when sanding with fine grits, this ridge often shows up as streaks.

- Better suited for coarse sanding or heavy stock removal, not finishing.

- Lap (Skived) Joints The belt ends are thinned (skived) and overlapped.

The overlap is glued and reinforced with tape on the back, not underneath the abrasive.

The joint runs smoothly through the sander and leaves fewer marks.

Stronger, longer lasting, and better for fine finishing.

Which Joint Should You Use? For woodworking, especially final sanding stages, lap joints are the better choice. They produce a smoother finish, reduce joint marks, and keep belts running more evenly. Butt joints still have their place in rough sanding, but they are not ideal when surface quality matters.

Key Takeaway If your goal is a clean wooden surface with minimal joint marks, choose skived lap joint belts with backing tape on the non-abrasive side. Save butt joints for coarse grit belts used in aggressive stock removal.

At Unified Tooling, we supply sanding belts designed for performance in every stage of woodworking. The right joint makes all the difference in your finish.