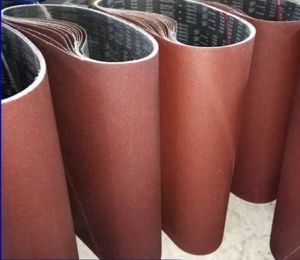

Silicon Carbide Sanding Belts

Silicon Carbide Sanding Belts: Uses and Applications

Silicon carbide sanding belts are engineered for aggressive cutting on hard and brittle materials. You’ll get sharp, consistent results with a uniform finish. These belts are best suited for applications where precision, speed, and surface quality matter.

What Makes Silicon Carbide Belts Different

- Harder and sharper than aluminium oxide

- Brittle grain that fractures easily, exposing new sharp edges

- Fast stock removal with a fine scratch pattern

- Performs well under low-to-medium pressure

Where You Can Use Silicon Carbide Sanding Belts

| Material Type | Common Applications |

|---|---|

| Wood (especially hardwoods) | Fine sanding, lacquer prep, finish removal |

| Glass | Edge smoothing, light shaping, scratch removal |

| Stone (marble, granite) | Honing, polishing prep, shaping |

| Ceramics | Deburring, surface finishing |

| Metals (non-ferrous) | Brass, copper, titanium—surface prep, burr removal |

| Plastic and composites | Clean finishing without melting, edge smoothing |

| Painted or coated surfaces | Paint stripping, feathering edges, finish sanding |

| Rubber | Shaping and surface texturing |

Industries That Rely on It

- Glass fabrication

- Stone and monument processing

- Furniture and cabinetry

- Automotive refinishing

- Metal polishing shops

- 3D printed part post-processing

- Composite and surfboard manufacturing

Available Options

You’ll find silicon carbide belts in various grits and backing types:

- Grit range: 24 (coarse) to 1200 (ultra-fine)

- Backing types: Cloth, waterproof polyester, paper

- Custom sizes: From handheld file belts to large wide belts for sanding lines

Best Practices

- Run belts at correct speed for the material—avoid excessive heat

- Use with proper contact wheels or platen supports

- Replace belts before the grain dulls to keep consistent finish quality